Dowel forms and rotary version Series 82, 66

Specifications

Dimensions

153 x 85 x 171 (h) cm

Net weight

418 kg

Compressed air consumption lt/cy at 6 bar

30

Absorbed power

1800 W

Daily output pairs

1200

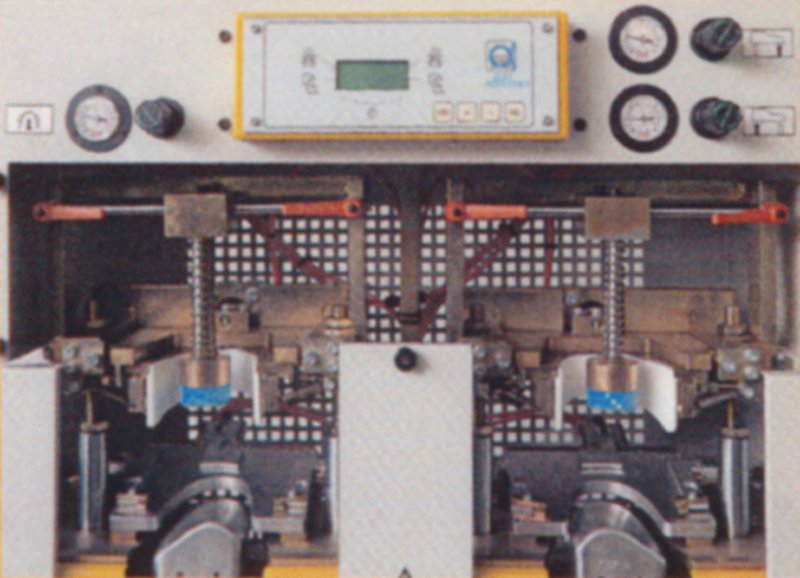

Alfa 82/2H

Toe upper forming machine.

ALFA 82 series toe forming machine has 2 heated stations to reactivate the toe and the tip of upper and two cold stations that, by a properly shaped aluminum moulds, give the shape to the uppers. The new series has a new powerful Hardware-Software. Infact by a single programmable terminal the operator can introduce any kind of set values of machine cycle, mould temperatures and receive warnings in case of malfunctions. The teflon group and the upper sipport plate have a new automatic system with adjustable pressue to give an excellent final result about the linearity of the border of upper and avoid the unpleasant wrinkles. Version Mod. 82/2H/PP has another important feature.

Available Models and optionals

ALFA 82/1H: Two stations equipped with chilled moulds for shaping the toe upper plus one preheating station for toe cap reactivation.

OPT/P: Adjustable system-pressing for tefoln toe band.

OPT/PP: Adjustable system-pressing for tefoln toe band and upper support plate.

Specifications

Dimensions

155 x 170 x 180 (h) cm

Net weight

Kg 900

Compressed air consumption lt/cy at 6 bar

100

Absorbed power

1750 W

Output per hour

200

Alfa 66

Rotating work station for reactivating and moulding toe caps.

The “ROTOMOULDER” is a rotating work station for the reactivation, moulding and flanging of toe caps.

The main advantages of this machine can be listed as follows:

– Increase in production with reduction in costs.

– Less fatigue for the operator.

– Low temperature processing resulting in less danger of damaging upper and lining leather.

– Elimination of dead times for reactivating and moulding.

The machine is composed of four rotating stations equipped with pre-heating, reactivating and combining the upper toe cap, and another on the left hand side for forming anf flanging the upper.

Once the two units have been loaded, the machine rotates automatically to position a new station in front of the operator ready to unload the upper and reload again. This operation eliminates the dead times previously wasted waiting for the pre-heating and combining. In addition, the operator is not required to move backwards and forwards from left to right as with standard type machines, thus reducing fatigue.

Since the completion of a whole cycle on each station means that the upper remains on the unit for a longer period of time, work temperatures can be maintened much lower, reducing the danger of damaging upper and lining leather.

Main features:

– Work surface for placing the upper to ensure perfect vision during work operation.

– Two side and one central adjustable register nuts for perfect upper positioning.

– Powerful refrigerant liqiud unit

– Electronic control card with programmable microprocessor.

– Automatic start up machine cycle and rotation.

– Photoelectric safety barrier.

Other models available

ALFA 67: External station of preheating positioning for toe cap reactivation.

ALFA 66/4H: Four stations equipped with chilled moulds for shaping the toe of the upper, plus four rotating preheated stations for toe cap reactivation.

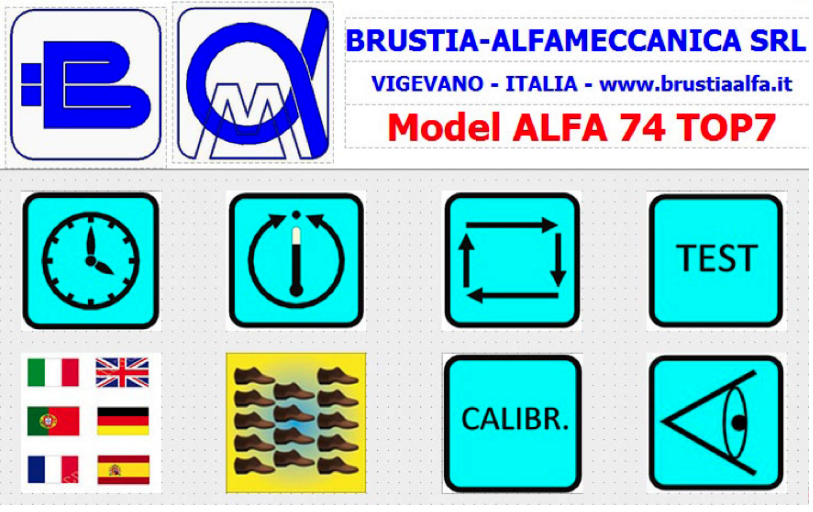

T7 color touch screen display with programming PLC

The T7 PLC line installed on the machines Brustia-Alfameccanica is, in accordance to INDUSTRY 4.0, an extraordinarily revolutionary concept of automation matching the robustness and reliability of PLC industrial with potential of interconnectivity and interfacing of the operating systems of the PC world.

The use of this tool has allowed to improve the machines electronic and mechanical performances, as well as to provide a more simple and easy handling for the operator of the working parameters.

In fact, the setting, programming and displaying of the various values appears much more immediate than a common display and can be performed remotely, as well as remotely can take place the data exchange from previous to next phases and assistance hardware/software. It is also possible to choose the programming language of the machine, perform a complete self-diagnosis, consult the machine manual, check the daily / periodic and total productivity and many other options!

Here is an example of TOP 7