Specifications

Dimensions

96 x 106 x 209 (h) cm

Net weight

Kg 480

Work pressure

6 bar

Supply voltage

380 V

Compressed air consumption lt/cy at 6 bar

24

Absorbed power

120 W

Daily output pairs

1600

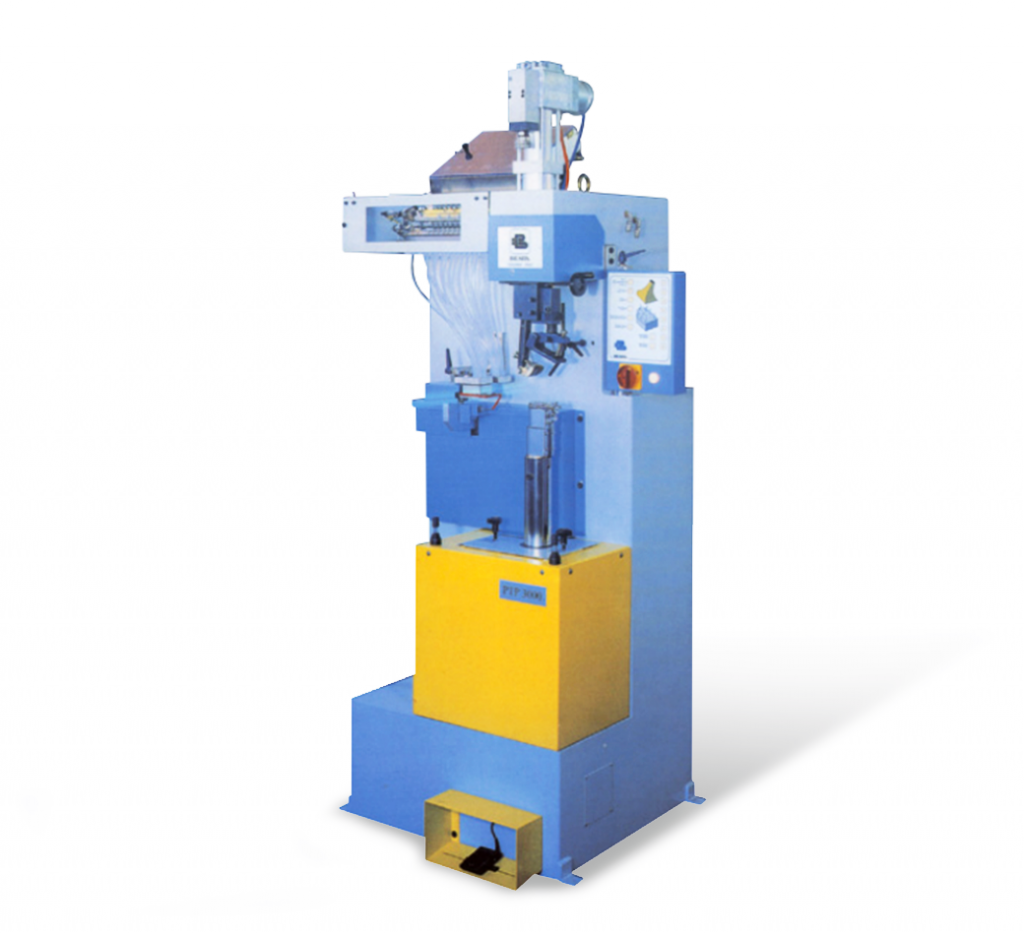

PTP 3000/NA

Automatic electronic heel nailing machine with direct nailing.

Main features:

- Programmable nailing cycles.

- Powerful nailing cylinder for any type of material.

- 16 nails or 15 nails + screw feeder divided into 4 sections for simultaneous use of different nails lengths conveyed in the nails holder blocks, system for quick exchange of the nails length in use.

- Nailing regulation device.

- Automatic release system in case of nails jam (optional).

- Movable column for boots.

- Quick exchange hold down.

- By request the machine can be set with “north/south” or “east/west” working position.

Specifications

Dimensions

80 x 60 x 210 (h) cm

Net weight

Kg 280

Compressed air consumption lt/cy at 6 bar

24

Absorbed power

120 W

Daily output pairs

1600

PTP 3001

Pneumatic automatic heel nailing machines with movable column for man, lady and boot working. Position north-south or east-west by request.

Available models and optionals

PTP 3001 S MAN: Sequential nailing and manual 7 nails feeding.

PTP 3001 S: Sequential nailing and semiautomatic 7 nails feeding.

PTP 3001 S AUT: Direct nailing and manual 7 nails feeding.

PTP 3001 MAN: Direct nailing and manual 7 nails feeding.

PTP 3001: Direct nailing and automatic 7 nails feeding.

PTP 3001 AUT: Direct nailing and automatic 7 nails feeding.

Optional: screw by request.

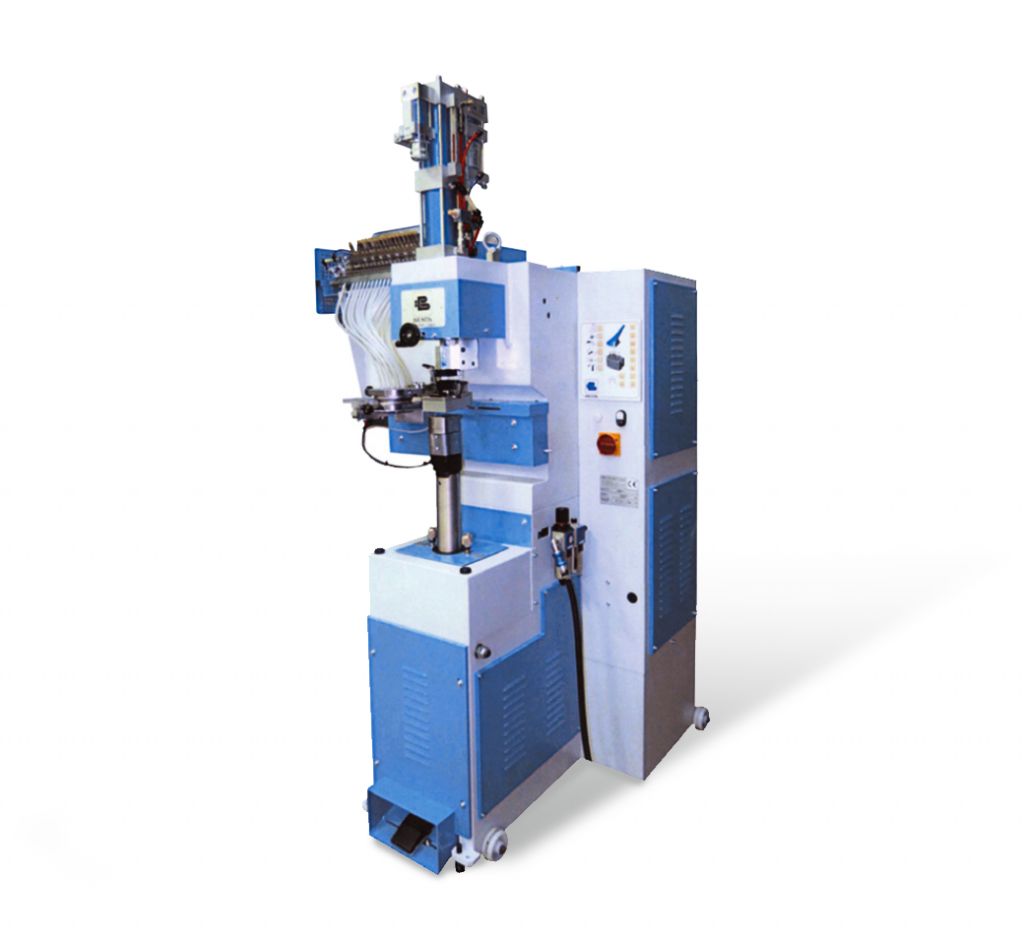

Specifications

Dimensions

115 x 115 x 210 (h) cm

Net weight

Kg 630

Oil tank

L 100

Compressed air consumption lt/cy at 6 bar

1,4

Absorbed power

120 W

Daily output pairs

1600

PTO 4000/NA

The new fashion of extreme shape and height heeels requires the use (for insoles and heels) of materials much more compact, rigid and stiff than ever before. These new materials make necessary that even the process of nailing heel needs an upgrade aimed at features of greater speed, power and precision of fit nails in the insole/heel.

Oue experience of over 55 years in nailing machines has led us to a machine with a Hydraulic nailing system that allows great speed, great power bat at the same time big accuracy in the process of nailing heel.

Here is the new born heel nailer PTO 4000 NA (non sequential nailing direct) equiped with hydraulic central device and with hydraulic nailing system.

The 4000 series is also equipped with a new electronic board with microprocessor of latest technology more reliable and versatile than ever before with nailing sequence fully programmable and machine cycles selected by the operator; it is also present an automatic troubleshooting when machine is switched on.

Main features:

- Loader 14 naisl + 2 screws or 16 nails divided in 6 selections.

- Boot working by movable nailing column.

- Nailing regulation device to adjust penetration of nails into insoles and drivers according to the different lenghts of nails.

- Device for quick change of nailing form and pneumatic hold down for any type of heels.

- Automatic nail blocs release in case of nails jam (either on nailing form or under nails slide bloc).

- Working position East-West or North-South upon request.

- Hydropneumatic hold down cylinder with holding up to 3000 Kg.

- Fully hydraulic nailing device with 7+1 cylinders in sequential nailing or in one big nailing cylinder for direct drive.

T7 color touch screen display with programming PLC

The T7 PLC line installed on the machines Brustia-Alfameccanica is, in accordance to INDUSTRY 4.0, an extraordinarily revolutionary concept of automation matching the robustness and reliability of PLC industrial with potential of interconnectivity and interfacing of the operating systems of the PC world.

The use of this tool has allowed to improve the machines electronic and mechanical performances, as well as to provide a more simple and easy handling for the operator of the working parameters.

In fact, the setting, programming and displaying of the various values appears much more immediate than a common display and can be performed remotely, as well as remotely can take place the data exchange from previous to next phases and assistance hardware/software. It is also possible to choose the programming language of the machine, perform a complete self-diagnosis, consult the machine manual, check the daily / periodic and total productivity and many other options!

Here is an example of TOP 7