Specifications

Dimensions

92 x 85 x 210 (h) cm

Net weight

Kg 450

Transformer

160 W

Electrical system

24V

Feeder

10

Nails length

6 to 20 mm

Output in 8 hours

up to 4800

PTP 995MA

Automatic electronic heel nailing machine for unit soles.

Pneumatic version.

The PTP 995MA is an automatic, pneumatic, electronic heel nailing machine purposely designed for soles factories in order to full fill all the working requirements. The machine is available also in oleodinamic version PTO 995 MA. It is equipped with hold-downs for high and flat heels and with 3 nailing forms easily interchangeable (working change requires a few seconds). The loader is with 10 nails from 6 to 20 mm. (divided into 2 sections) equipped with 2 sensors (till 8 by request) for the automatic detection of nails lackage or loading troubles; there is a device for the automatic nails discarge useful whel, due to a working change, a nails length different from the one in use is required. The cycle start control is given by a feeler placed in the pincer and acted by the rear part of the sole. This pincer assures to center the sole checking the correct position on the nailing form before activation of nailing and lateral discharge. During the whole cycle of clamping, nailing and discharging, the working area is safeguarded in the front and side by protection plexiglasses.

The weltpressuring device is made by a plate which is selfadjusting in height for the different thickness or for the soles without welt and acts with a pressure adjustable from the command panel. It is also adjustable from the panel the power of nailing drivers which can be reduced for soft material soles or increased for hard material soles. The drivers position is adjustable either for the outcoming/penetration into the sole during nailing either for the different length of nails. In case the nails are jammed during the pipes/nailsblock/nailing form loading, the release is prompt and automatic.

The heel clamping is made by an oleodinamic cylinder (adjustable power) with a fast approach movement and by a wide regulation pressing run, in order to avoid braekages in thin heels and having enough power to press big heels. The high speed allows a productivity of 500/600 pairs per hour according to the different working types. The machine is equipped with all the safety measures required by present law and particular attention has been given to energy saving.

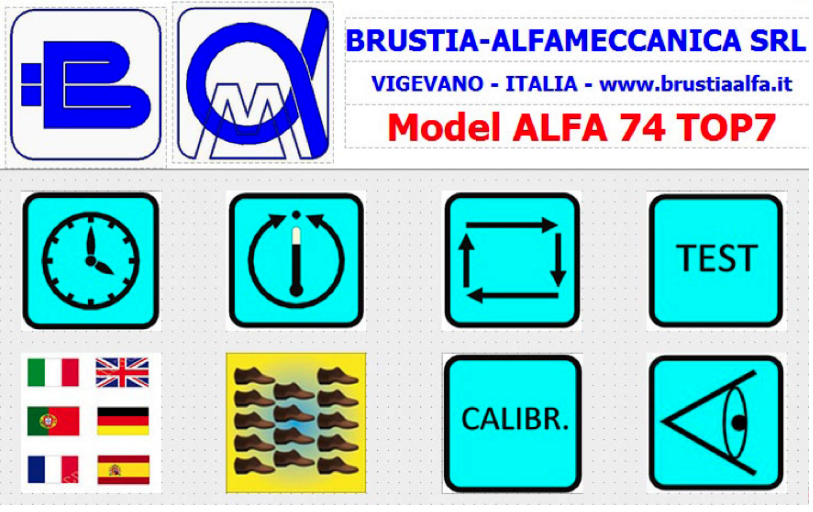

T7 color touch screen display with programming PLC

The T7 PLC line installed on the machines Brustia-Alfameccanica is, in accordance to INDUSTRY 4.0, an extraordinarily revolutionary concept of automation matching the robustness and reliability of PLC industrial with potential of interconnectivity and interfacing of the operating systems of the PC world.

The use of this tool has allowed to improve the machines electronic and mechanical performances, as well as to provide a more simple and easy handling for the operator of the working parameters.

In fact, the setting, programming and displaying of the various values appears much more immediate than a common display and can be performed remotely, as well as remotely can take place the data exchange from previous to next phases and assistance hardware/software. It is also possible to choose the programming language of the machine, perform a complete self-diagnosis, consult the machine manual, check the daily / periodic and total productivity and many other options!

Here is an example of TOP 7