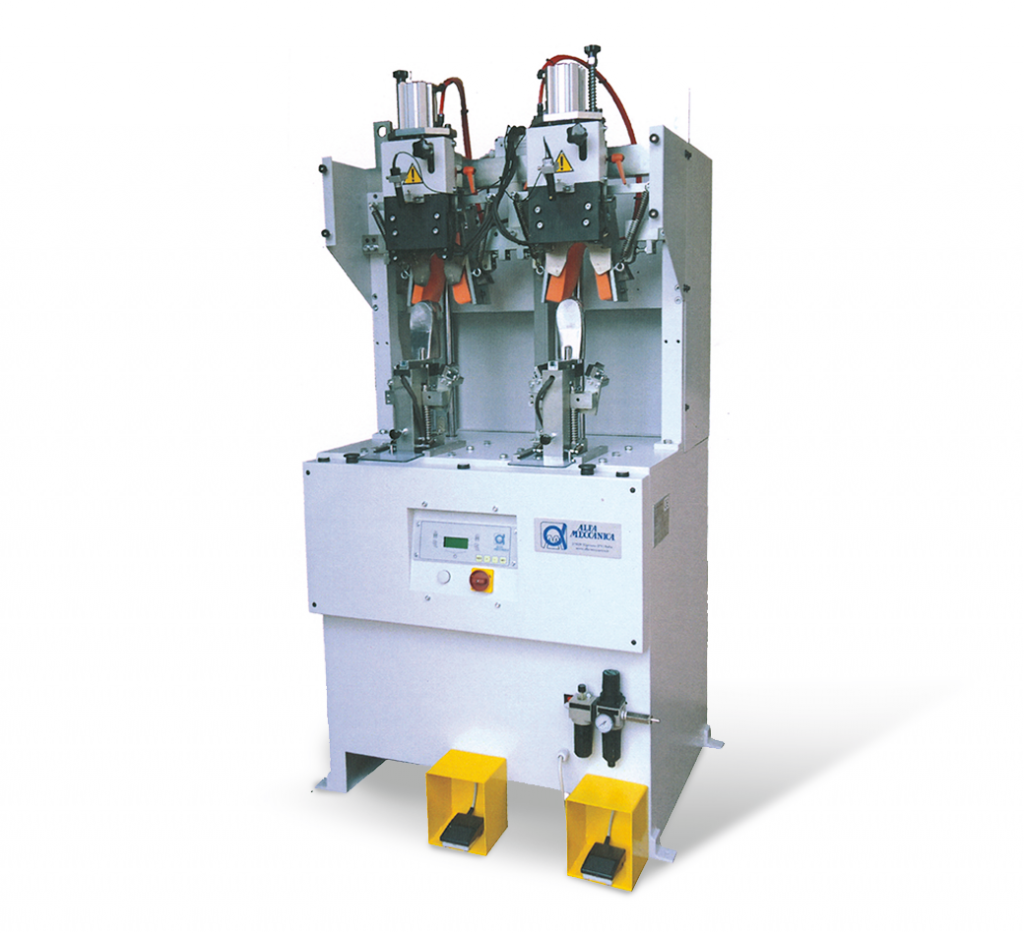

Specifications

Dimensions

95 x 85 x 190 (h) cm

Net weight

Kg 413

Air consumption liters x cycle at 6 bar

85

Power consumption

3000 W

Daily pair production

1100

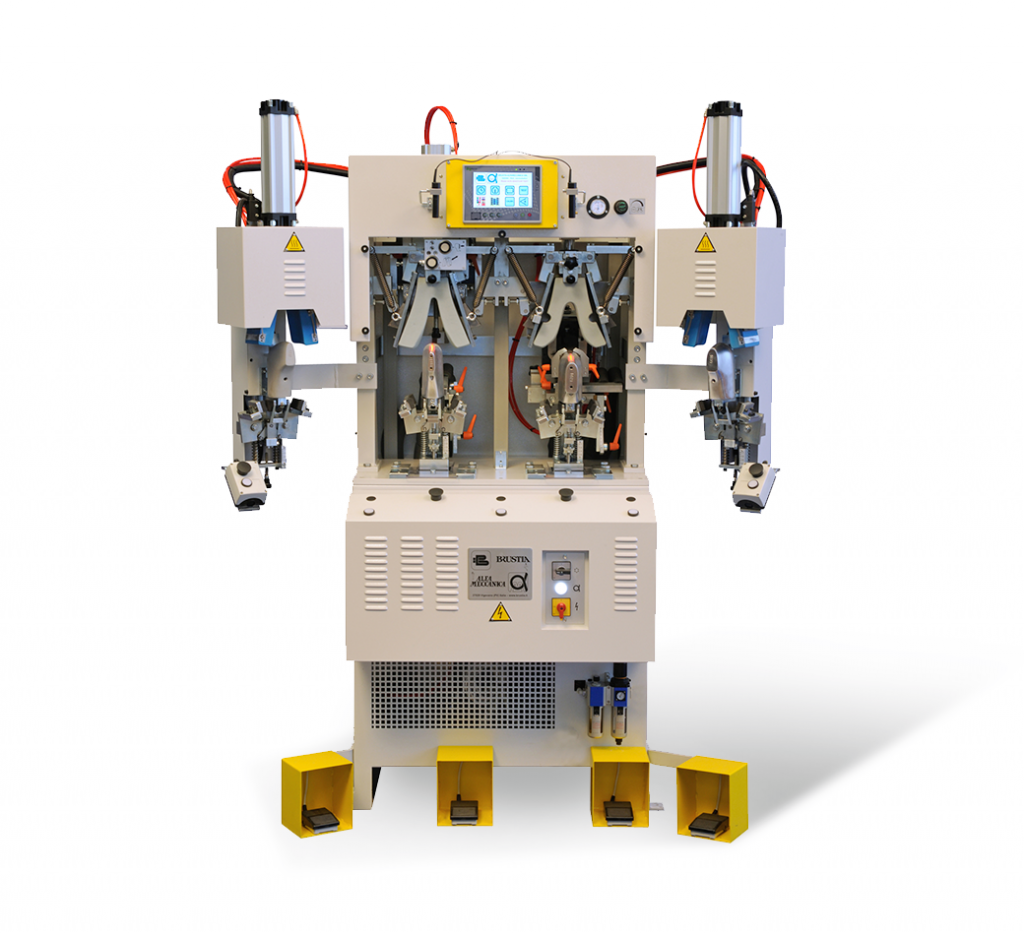

Alfa 685 CF2HP

Hot and cold Backpart moulding machine with inner-outer moulds and wipers rotating to set machine for standard and mocassino working position.

Two cold stations with pulling pincers and flanging wipers. Rotating system to set standard or mocassino working position.

Two hot reactivating stations with pulling pincers.

Main features:

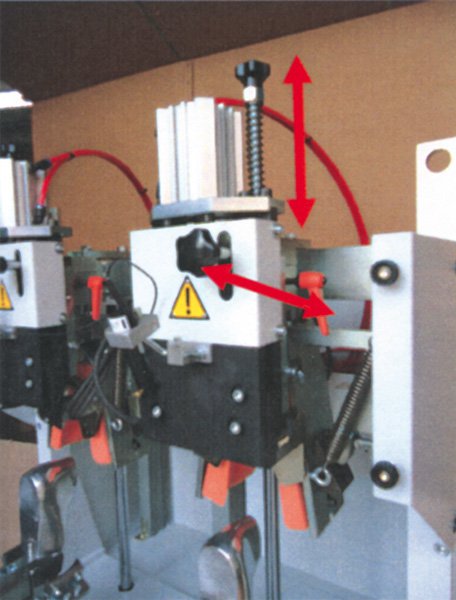

- Movable mould and pincer support for an easier upper positioning.

- Up and down regulating flanging wipers for different mould type (child, lady, man).

- Red Led optical projector light.

- Horizontal and vertical independent pincer regulation to have inclination pulling direction.

- LCD back light Display to insert hot and cold mould and cushion temperature values and cycle parameters.

Specifications

Dimensions

156 x 85 x 200 (h) cm

Net weight

Kg 571

Compressed air consumption lt/cy at 6 bar

87

Electrical consumption

2700 W

Daily output pairs

1100

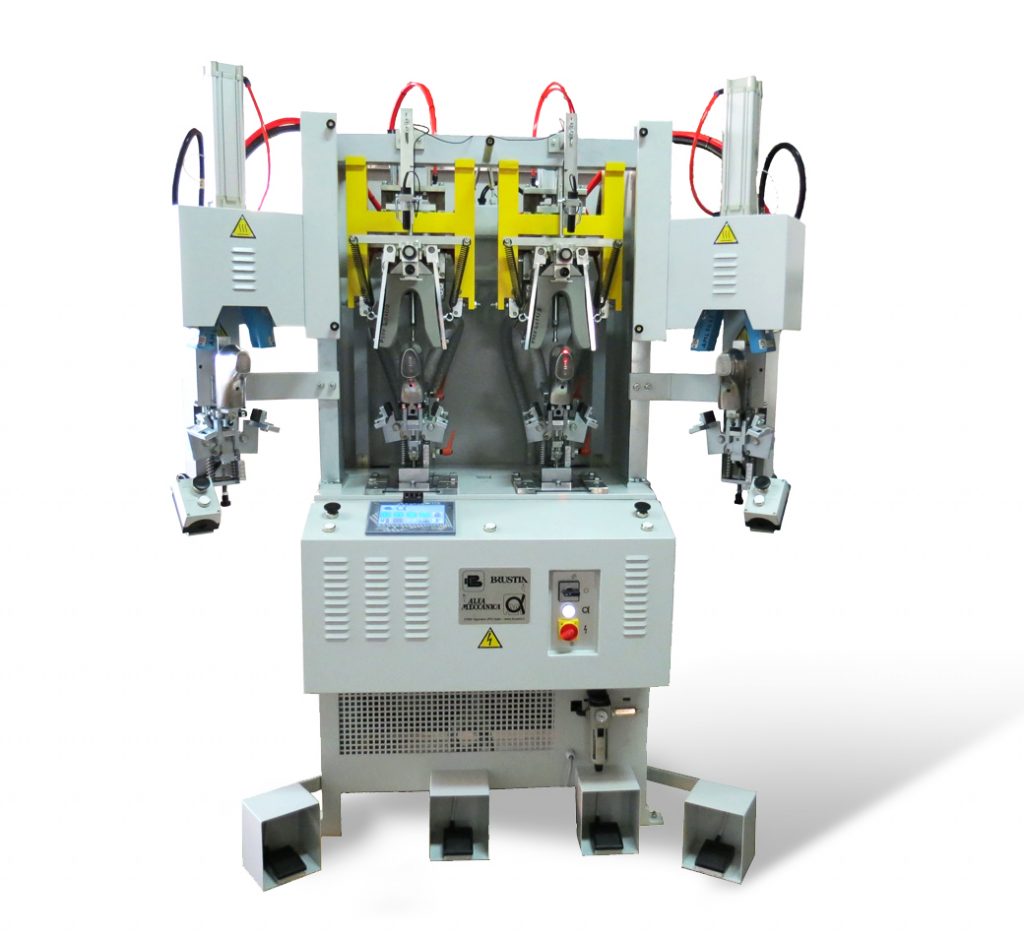

Alfa 684 CF2HP/M

The series update ALFA 684 The upgrade of the ALFA 684 Hot/Cold, gcounter moulding machine for thermoplastic and thermomboard counter has been developped considering the most recent request of our customers that is the handy

use and containment of work space NEW ALFA 684 Hot/Cold has small dimensions with a new frame design with more linear and rational surface and a new powerful Hardware-Software that gives the operator the possibility to control all machine fuctions by a single terminal. Infact the operator can introduce any kind of set values of machine cycle, hot and cold mould temperatures and also receive warnings in case of malfunctions.

Main features:

- Complete adjustment for outer and inner moulds, flanging wipers and pincers gives the possibility to work from baby size to men size included snow board boots.

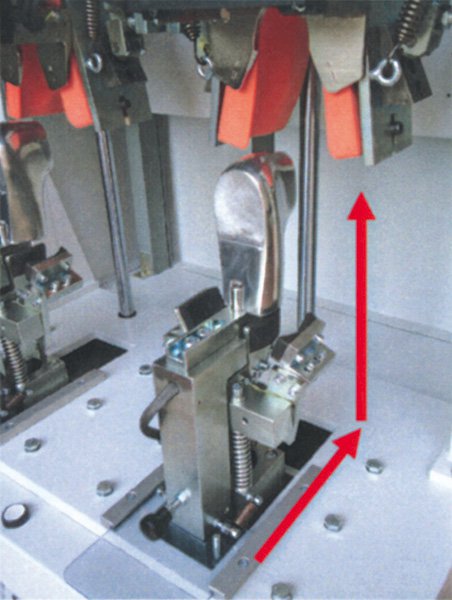

- The operating cycle is marked by the column moving up to the rubber cushion that closing makes wiper movement.

- Optical projector or pneumatic positioning upper device for models with wipers.

- The operating cycle is marked by the column moving up to the rubber cushion that closing makes wiper movement.

Available models and optionalals

ALFA 684F: Two stations equipped with heated moulds and plates for folding over seat edges.

ALFA 684C: Two stations equipped with chilled moulds.

ALFA 684CF: Two stations equipped with chilled moulds and plates for folding over seat edges.

ALFA 684C2HP: Two stations equipped with chilled moulds plus two pre-heated stations with upper pulling gripper.

ALFA 684CF2HP: Two stations equipped with chilled moulds and plates for folding over seat edges plus two pre-heated stations with upper pulling grippers.

OPT/M: Moulds, cushions, wipers and pincers positioned for Mocassino working.

OPT/GY: Arranged machine for Good Year work.

OPT/PR: Adjustable width of pincers.

OPT/P: Programmable pulling pincers.

OPT/FT: Safety photoelectric barrier system.

OPT/HP: Indipendent pre-heated station with upper pulling gruppers.

Specifications

Dimensions

95 x 85 x 190 (h) cm

Net weight

Kg 413

Compressed air consumption lt/cy at 6 bar

85

Electrical consumption

2000 W

Daily output pairs

1500

Alfa 686F

Backpart moulding machine for tempering and garbling of buttress with tile in inverted position and upper loading from inside. Two hot stations with pulling pincers and flanging wipers.

Main features:

- Heel aluminium moulds positioned in front of the operator.

- Movable mould and pincer support for an easier upper positioning

- Up and down regulating flanging wipers for different mould type (child, lady, man)

- Horizontal regulation flanging wipers for different thickness of counters and uppers

- Red Led optical projector light.

- Pincer positioning regulation to the mould.

- LCD back light Display to insert hot and cold mould and cushion temperature values and cycle parameters.

T7 color touch screen display with programming PLC

The T7 PLC line installed on the machines Brustia-Alfameccanica is, in accordance to INDUSTRY 4.0, an extraordinarily revolutionary concept of automation matching the robustness and reliability of PLC industrial with potential of interconnectivity and interfacing of the operating systems of the PC world.

The use of this tool has allowed to improve the machines electronic and mechanical performances, as well as to provide a more simple and easy handling for the operator of the working parameters.

In fact, the setting, programming and displaying of the various values appears much more immediate than a common display and can be performed remotely, as well as remotely can take place the data exchange from previous to next phases and assistance hardware / software. It is also possible to choose the programming language of the machine, perform a complete self-diagnosis, consult the machine manual, check the daily / periodic and total productivity and many other options!

Here is an example of TOP 7