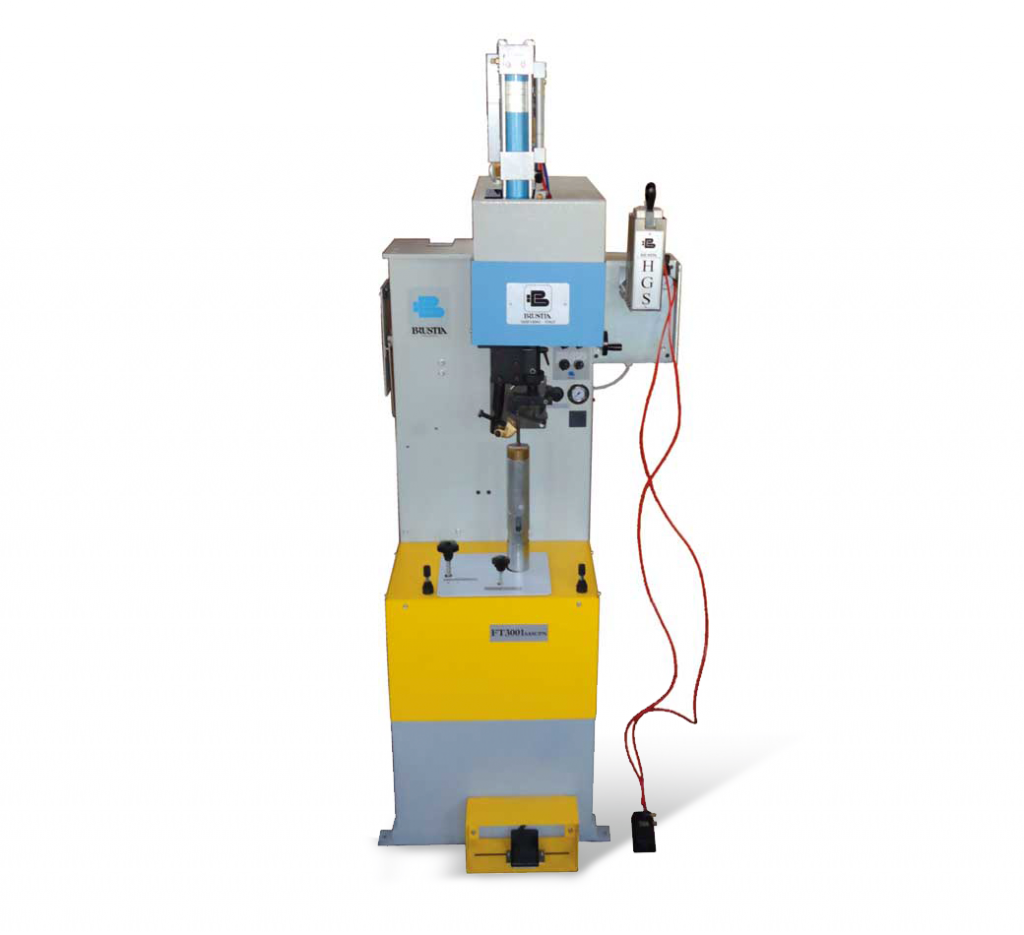

FT 3001SA/SC

Automatic electronic pneumatic heel pre-fixing/attaching machine with programmable work cycle.

Main features:

- Completely programmable work-cycle.

- Loader for two types of screw/four types of screw.

- Mobile form for working on boots.

- Pneumatic hold down for high and flat heels.

- Automatic or manual screw loading.

- Extremely silent and rapid work-cycleo.

- Traditional thermoplastic heater or fusor for polyurethene/thermoplastic cartridges.

FT 3001/SA: without screw feeder.

FT 3001 – 2V /4V: automatic loader for 2/4 different types of screw.

Optional:device for adjustable screw positioning for uncasted shoes..

Optional SC: screw spinning device for all types of screw.

FT 3001A-SC

Automatic electronic pneumatic heel pre-fixing/attaching machine with programmable work cycle.

Main features:

- Completely programmable work-cycle.

- Loader for two types of screw/four types of screw.

- Mobile form for working on boots.

- Screw attachment with higher-powered cylinder for hard materials.

- Pneumatic hold down for high and flat heels.

- Automatic or manual screw loading.

- Extremely silent and rapid work-cycleo.

- Traditional thermoplastic heater or fusor for polyurethene/thermoplastic cartridges.

FT 3001/SA: without screw feeder.

FT 3001 – 2V /4V: automatic loader for 2/4 different types of screw.

Optional:device for adjustable screw positioning for uncasted shoes..

Optional SC: screw spinning device for all types of screw.

T7 color touch screen display with programming PLC

The T7 PLC line installed on the machines Brustia-Alfameccanica is, in accordance to INDUSTRY 4.0, an extraordinarily revolutionary concept of automation matching the robustness and reliability of PLC industrial with potential of interconnectivity and interfacing of the operating systems of the PC world.

The use of this tool has allowed to improve the machines electronic and mechanical performances, as well as to provide a more simple and easy handling for the operator of the working parameters.

In fact, the setting, programming and displaying of the various values appears much more immediate than a common display and can be performed remotely, as well as remotely can take place the data exchange from previous to next phases and assistance hardware/software. It is also possible to choose the programming language of the machine, perform a complete self-diagnosis, consult the machine manual, check the daily / periodic and total productivity and many other options!

Here is an example of TOP 7